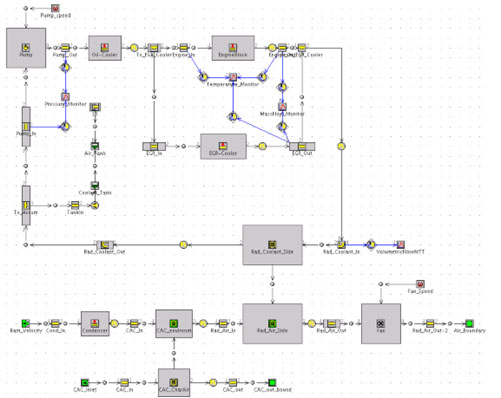

Cooling system

Design and develop full engine or vehicle level cooling system for different application including hybrid vehicles can be simulated based on customer requirement

.

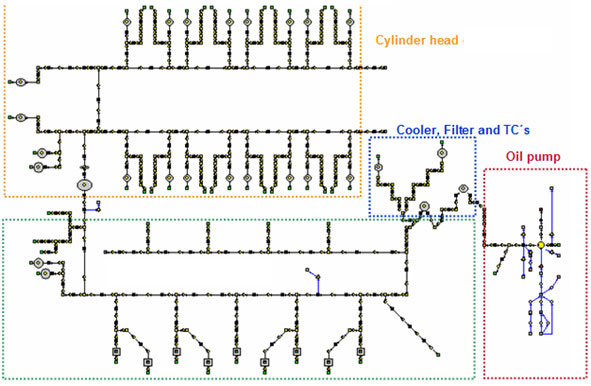

Lubrication system

1D lubrication analysis can be used during design phase to optimize all variants�of lubrication components and systems level analysis can be performed.

Steady state pressure and flow rate distribution for all oil consumers with pump sizing can be investigated. A transient thermal warmup model by integrating with cooling system model to predict energy consumption by the oil pump over driving cycle can be performed.

Thermal simulation

Full powertrain in vehicle thermal simulation to investigate fuel economy benefits can be modeled. Cylinder head, block including cranktrain inertias, cooling, lubrication system and vehicle model are included to predict fuel economy benefits during NEDC cycle. Further different thermal strategy can be investigated to optimize fluid warm up.

The term “thermal management” describes the efficient control of thermal energy from IC engine in combination with the vehicle package with the specific requirements under different operating and load conditions.

As a result, vehicle emissions can be reduced, also the thermal state, friction torque and mechanical engine efficiency can be improved. This leads to lower fuel consumption and improved engine life.

Engine simulation

1D engine simulation is widely used in many engine design department during concept development phase, research and development areas to calculate

- Burn rate calculation from measured cylinder pressure trace

- Gas exchange processes analysis

- Exhaust and intake manifold design and tuning

- Valve profile and timing optimization

- Supercharger/ turbocharger selection

- Transient response evaluation of turbocharger/ supercharger

- EGR system selection

- DOE analysis and optimization of engine performance parameters, etc.